product

Cutting-edge Design ---------------------------------------------------------------------------------------------

Cutting-edge Design ---------------------------------------------------------------------------------------------

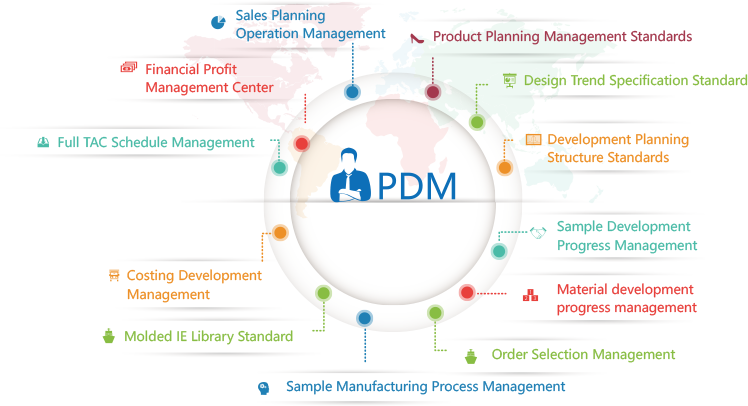

PDM is based on technology software to manage effectively all product-related information (including electronic documents, digital document database records, etc.) and all product-related technology processes (including approval / distribution, engineering changes, general processes, configuration management, etc.) .

PDM can manage effectively the enterprise's intellectual assets and improve the efficiency of the design process. At the same time, through the application of pre-configured industry best practices in daily engineering tasks and processes, it can explain the process of innovation and change, so that faster, shorter time. The lower cost of the market to introduce more competitive products

![]()

Solution Value -----------------------------------------------------------------------------------------------------

![]()

Module Function ---------------------------------------------------------------------------------------------------

![]() Multinational Factory Synchronization At Any Time ------------------------------------------------------

Multinational Factory Synchronization At Any Time ------------------------------------------------------

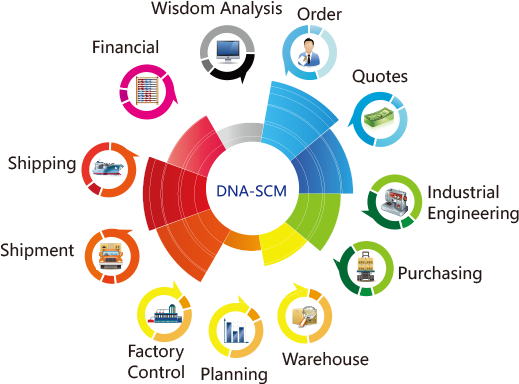

The core role of the system is to establish a business collaboration platform to eliminate information silos; from orders, quotes to process contract management; from the surface of the procurement of materials, warehousing to manufacturing planning scheduling management; from the production progress JIT control to finished goods ship From the financial cost profit and loss to business intelligence decision-making, all-round, the whole process for the business to provide comprehensive, timely and accurate decision support and control.

![]()

Solution Value -----------------------------------------------------------------------------------------------------

![]()

Module Function ---------------------------------------------------------------------------------------------------

![]()

Information Integration Manufacturing collaboration ---------------------------------------------------

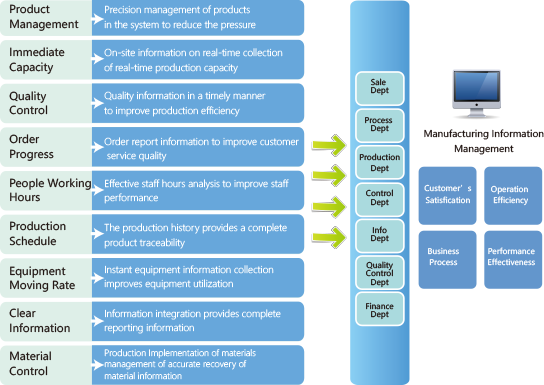

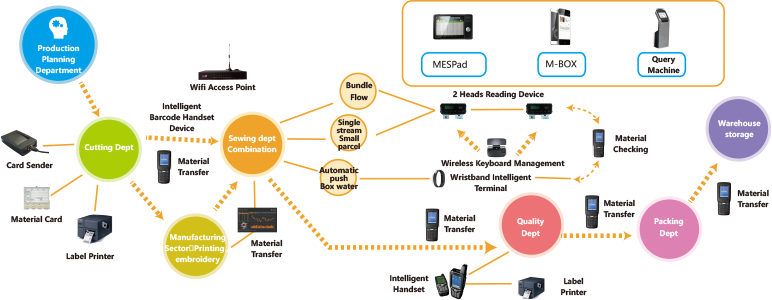

MES helps companies to collect and monitor the production data generated during the manufacturing process from order receipt, production, process control to product completion, to ensure the production quality of the application system. Through information-related technologies such as relational databases, graphical user interfaces, and open architectures, MES can produce online real-time production information from factories, and accurately transmit them to users for monitoring by Web or other notification methods. It also provides information on the state of the emergency and informs the user as quickly as possible.

From the company received the customer orders, then ship to the customer,

the middle of the production process control, is the MES system to play a function of the place.

![]()

Solution Value ----------------------------------------------------------------------------------------------------

![]()

Work Process -------------------------------------------------------------------------------------------------------

![]() Solution Value --------------------------------------------------------------------------------------------------------------

Solution Value --------------------------------------------------------------------------------------------------------------

![]()

方案价值 --------------------------------------------------------------------------------------------------------------

![]()

核心功能 --------------------------------------------------------------------------------------------------------------

![]()

技术方案 - 整体架构 ------------------------------------------------------------------------------------------------